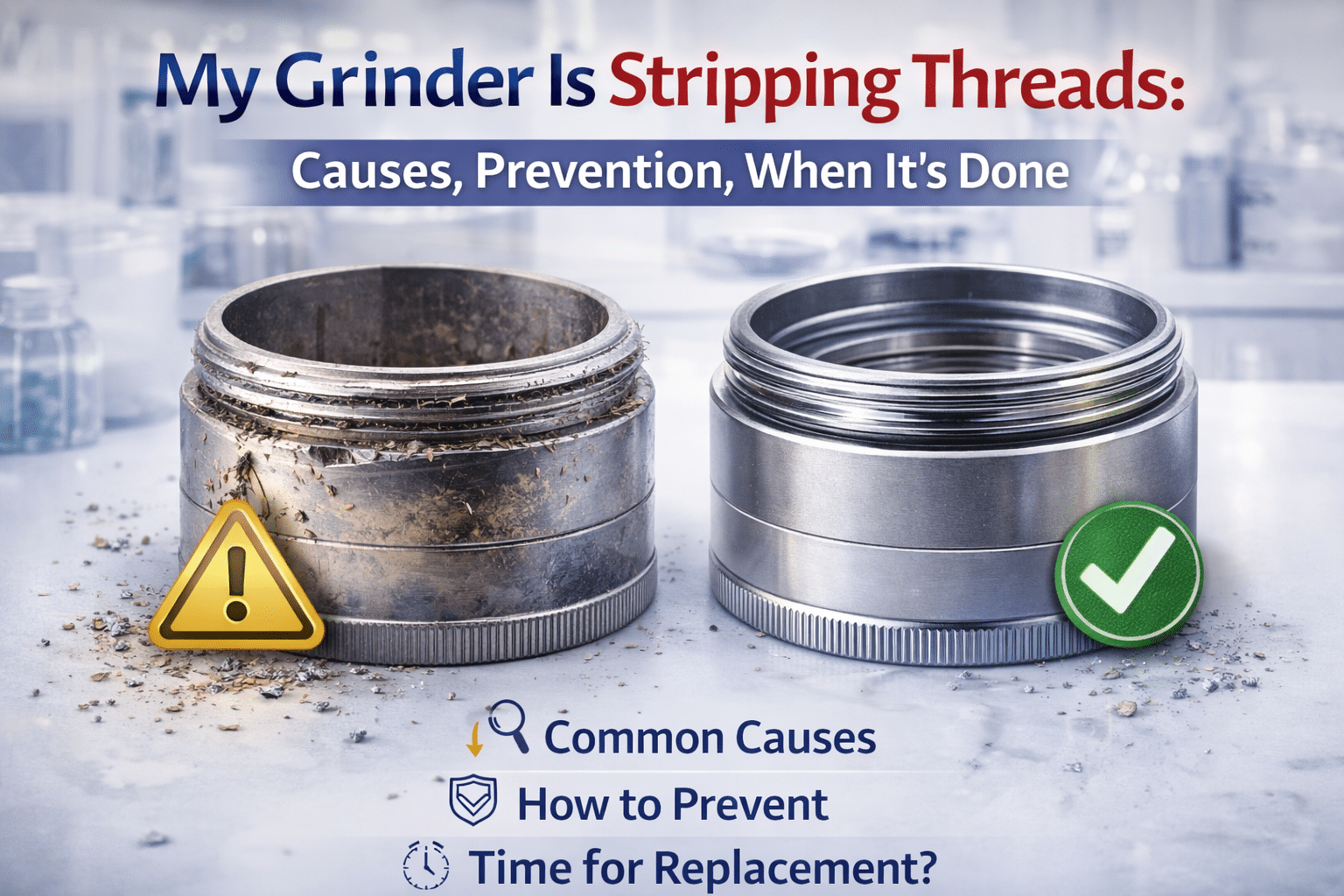

Thread stripping is one of the most frustrating grinder failures because it doesn’t happen all at once. It starts subtly — a lid that feels gritty, a catch that doesn’t seat cleanly — and then suddenly the grinder won’t stay together, cross-threads constantly, or spins forever without tightening.

If you’re here, you’re probably already past the “is this normal?” phase.

This guide breaks down exactly why grinder threads strip, how to slow or stop the damage, what doesn’t work, and the honest truth about when a grinder is finished. No fluff. No myths. Just mechanics.

What “Stripped Threads” Actually Means in a Weed Grinder

Thread stripping occurs when the male and female threads no longer interlock correctly. In grinders, this usually happens because:

- Material has been worn away

- Threads have deformed under load

- Resin buildup has caused misalignment and galling

Once thread geometry is compromised, alignment worsens exponentially.

Important distinction:

- Dirty threads ≠ stripped threads

- Cross-threaded once ≠ stripped

- Free-spinning with no bite = stripped

The Most Common Causes of Grinder Thread Stripping

1️⃣ Cross-Threading (The Silent Killer)

Cross-threading happens when the lid is started off-axis and forced down anyway.

Why this is so damaging:

- Aluminum threads are fine-pitch

- Even slight misalignment causes metal-on-metal shaving

- Each incorrect start removes material permanently

Once enough material is gone, threads can no longer self-correct.

This is most common on:

- Threaded 2-piece grinders

- Heavily used 3-piece grinders

Examples:

https://tahoegrinderco.com/product-category/all-products/2-piece-weed-grinders/

https://tahoegrinderco.com/product-category/all-products/3-piece-weed-grinders/

2️⃣ Resin Buildup Creating False Resistance

This one tricks people.

Resin buildup:

- Makes threads feel “tight”

- Causes users to apply extra torque

- Masks misalignment

What’s actually happening:

You’re grinding resin into the threads while forcing the lid, which accelerates wear and increases friction heat.

If your grinder suddenly feels harder to close:

👉 Stop tightening — clean it

Helpful maintenance accessories live here:

https://tahoegrinderco.com/product-category/all-products/smoking-accessories/

3️⃣ Over-Tightening (Torque Damage)

Grinders do not need to be cranked down.

Over-tightening causes:

- Thread compression

- Micro-deformation

- Flattening of thread peaks

Once threads lose their defined edges, they begin slipping instead of locking.

This is especially common with:

- Large diameter grinders

- Desk grinders

- Heavy-use grinders

Examples:

https://tahoegrinderco.com/product-category/all-products/4-piece-weed-grinders/

https://tahoegrinderco.com/product-category/all-products/worlds-largest-weed-grinder/

4️⃣ Poor Thread Machining (It’s Real)

Not all threads are created equal.

Low-quality grinders often have:

- Shallow thread depth

- Inconsistent pitch

- Burrs left from poor machining

These grinders:

- Feel fine initially

- Strip quickly under real use

- Cannot be “saved” long-term

This is why precision-machined grinders last significantly longer:

https://tahoegrinderco.com/product-category/all-products/

5️⃣ Dropping the Grinder (Impact Misalignment)

A drop can:

- Slightly ovalize the thread opening

- Bend the mating surface

- Introduce permanent off-axis engagement

From then on, every twist damages threads further — even if you’re careful.

Early Warning Signs Your Threads Are Failing

Pay attention to these symptoms:

- Lid spins without tightening

- You feel “gravel” when turning

- Threads catch, then slip

- Grinder only closes when forced

- Lid pops loose during use

If you notice two or more of these, damage is already occurring.

Can Stripped Grinder Threads Be Fixed?

❌ What Does NOT Work

- Bending threads back

- Filing or sanding

- Adding tape, wax, or grease

- “Just tightening harder”

These are temporary hacks that accelerate failure.

⚠️ Temporary Stabilization (Short-Term Only)

If threads are partially stripped:

- Clean threads thoroughly

- Align carefully

- Tighten minimally

- Accept reduced lifespan

This buys time — it does not restore integrity.

When a Grinder Is Officially Done

A grinder is beyond recovery when:

- Threads free-spin consistently

- Lid cannot stay seated

- Cross-threading happens every attempt

- Metal shavings appear

- Alignment can’t be corrected

At this point, continuing to use it risks:

- Metal contamination

- Flower waste

- Frustration every session

Replacement is the correct call.

Why Magnetic Grinders Avoid This Entire Problem

Magnetic grinders eliminate threads entirely.

Advantages:

- No thread wear

- Perfect alignment every time

- Faster access

- No resin-packed threads

This is why most modern premium grinders have moved away from threading.

Examples:

https://tahoegrinderco.com/product-category/all-products/3-piece-weed-grinders/

https://tahoegrinderco.com/product-category/all-products/4-piece-weed-grinders/

Threaded vs Magnetic: Longevity Comparison

Threaded grinders

- Wear-based failure

- Require careful handling

- Finite lifespan

Magnetic grinders

- Minimal mechanical wear

- Resin is main maintenance concern

- Significantly longer service life

Best Practices to Prevent Thread Stripping

Every Time You Close the Grinder

- Start threads gently

- Rotate backwards until threads “drop”

- Then tighten forward lightly

Weekly

- Clean thread area

- Remove resin before it hardens

Always

- Never force resistance

- Never overtighten

- Never close while misaligned

Grinder Types Most at Risk

- Small threaded grinders

- Cheap acrylic grinders

- Poorly machined imports

More durable options:

https://tahoegrinderco.com/product-category/all-products/2-piece-weed-grinders/

https://tahoegrinderco.com/product-category/all-products/wooden-weed-grinders/

The Honest Truth About Stripped Threads

Thread stripping isn’t bad luck.

It’s the result of:

- Misalignment

- Resin neglect

- Over-torque

- Inferior machining

Once threads are gone, they’re gone.

The fix isn’t clever hacks — it’s better design, better habits, and knowing when to replace.

Final Takeaway

If your grinder threads are stripping:

- Stop forcing it

- Clean immediately

- Use gentle alignment

- Understand the lifespan reality

And if it’s already free-spinning?

That grinder has done its job.

Move on to designs that remove the failure point entirely and keep your sessions smooth instead of frustrating.

If you want long-term reliability, browse grinders built for real use, not disposable wear:

https://tahoegrinderco.com/product-category/all-products/

When mechanics are respected, grinders last.