Cleaning a weed grinder is only half the job.

If your grinder feels rough, squeaky, grabby, or misaligned after cleaning, the issue isn’t damage — it’s improper drying, incorrect reassembly, or skipping the break-in phase. Most grinders that “never felt the same again” were simply put back together too early or without resetting contact surfaces.

This guide explains how to restore factory-smooth performance after cleaning, step by step, without lubricants, hacks, or shortcuts that ruin tolerances.

Why Grinders Feel Bad After Cleaning (It’s Not What You Think)

After cleaning, grinders often feel:

- Dry and scratchy

- Hard to turn

- Misaligned

- Noisy or squeaky

This happens because cleaning removes resin micro-films that previously acted as a natural buffer between metal surfaces. When bare metal meets bare metal too soon — especially while damp — friction spikes.

This is normal and temporary if handled correctly.

High-precision grinders designed to recover properly:

https://tahoegrinderco.com/product-category/all-products/

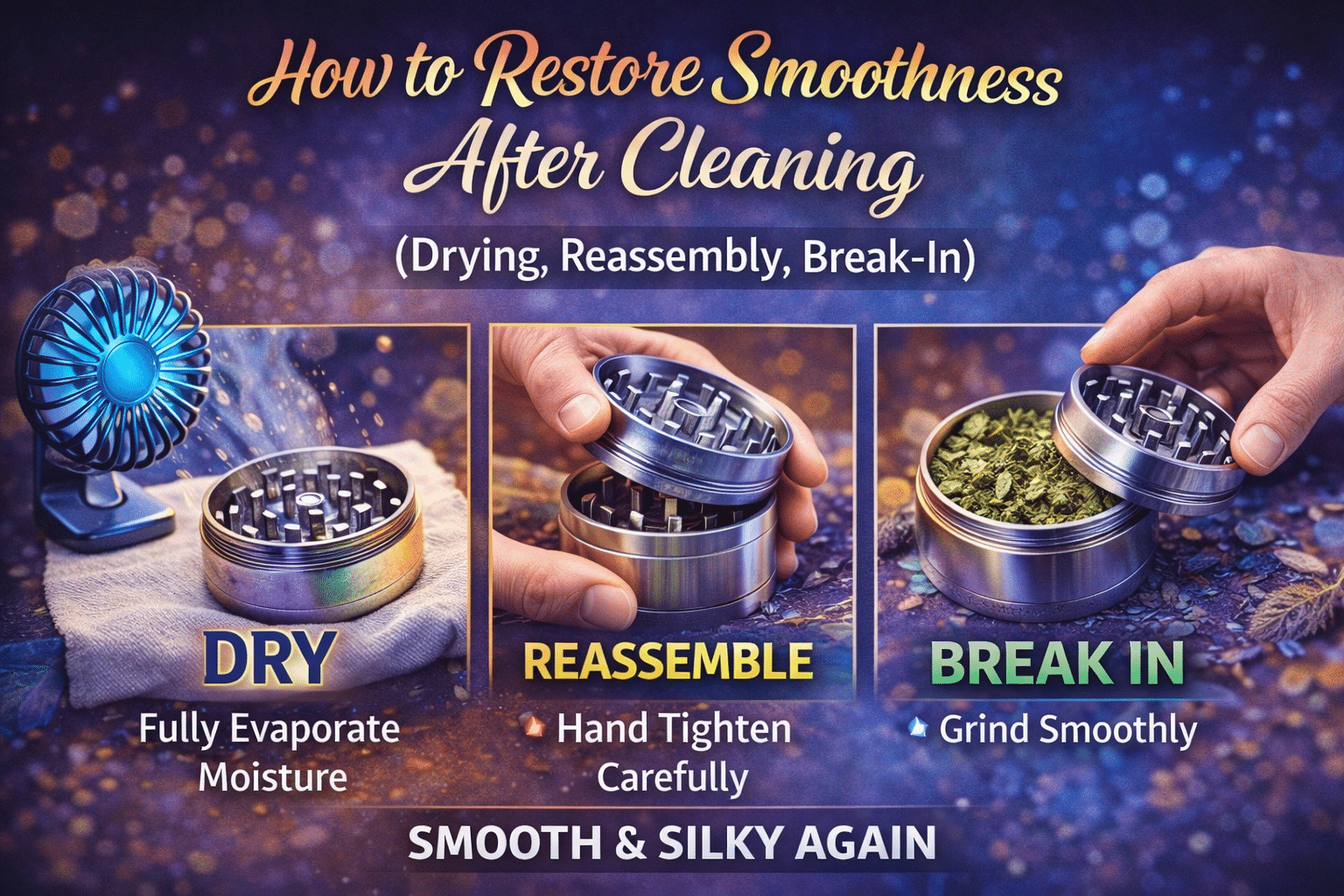

Phase 1: Proper Drying (The Most Skipped Step)

Never Reassemble a Grinder While Damp

Even trace moisture causes:

- Metal drag

- Temporary surface oxidation

- Resin smear instead of separation

Correct drying method:

- Pat each piece dry with lint-free cloth

- Air dry fully separated

- Minimum drying time: 12–24 hours

Do not:

- Use heat guns

- Oven dry

- Reassemble “mostly dry”

Grinders with tight tolerances are especially sensitive:

https://tahoegrinderco.com/product-category/all-products/2-piece-weed-grinders/

Phase 2: Inspect Before Reassembly

Before putting anything together, check:

- Teeth for trapped fibers

- Magnets for residue

- Threads or mating surfaces for buildup

- Screen chamber edges (if applicable)

If debris remains, smoothness will not return.

Relevant designs:

https://tahoegrinderco.com/product-category/all-products/3-piece-weed-grinders/

Phase 3: Correct Reassembly Order (This Matters)

Many grinders feel “off” simply because they’re reassembled incorrectly.

Standard Reassembly Order

- Grinding teeth halves

- Storage chamber (if applicable)

- Screen section (4-piece only)

- Kief catcher

Never tighten aggressively. Let gravity and alignment do the work.

4-piece configurations:

https://tahoegrinderco.com/product-category/all-products/4-piece-weed-grinders/

Phase 4: Dry Spin Reset (Critical Step)

Before adding flower:

- Rotate grinder empty

- Slow turns only

- 10–15 full rotations

This:

- Reseats contact surfaces

- Clears micro-friction

- Restores alignment memory

If resistance decreases gradually — that’s perfect.

If resistance increases — stop and re-inspect.

Phase 5: Natural Break-In (No Lubes, Ever)

Why You Should Never Lubricate a Grinder

Oil, wax, graphite, or “food-safe lubricants”:

- Trap resin

- Create sludge

- Destroy grind consistency

- Void longevity

Instead, use natural resin re-conditioning.

Proper Break-In Method

- Add a small, dry nug

- Grind lightly (don’t force)

- Empty immediately

- Repeat 2–3 times

This deposits a microscopic resin layer that restores smooth rotation without contamination.

Grinders engineered for this process:

https://tahoegrinderco.com/product-category/all-products/worlds-largest-weed-grinder/

What If Your Grinder Still Feels Rough?

Common Fixes by Symptom

Squeaking

- Caused by dry metal contact

- Fix: more dry spins + light resin break-in

Binding

- Caused by debris or misalignment

- Fix: disassemble and inspect mating surfaces

Grinding feels uneven

- Caused by incomplete drying

- Fix: wait another 12 hours

Thread resistance

- Caused by micro-resin in threads

- Fix: dry brush only, no scraping

Threaded models:

https://tahoegrinderco.com/product-category/all-products/square-grinders/

How Long Until Full Smoothness Returns?

Typical timeline:

- Immediate improvement after dry spins

- 80% smoothness after first break-in

- 100% smoothness after 3–7 normal sessions

If smoothness never returns, the grinder was either:

- Reassembled wet

- Scraped during cleaning

- Forced while misaligned

Preventing Post-Cleaning Issues Next Time

Best practices:

- Clean less often, not more

- Never scrape metal on metal

- Avoid soaking longer than necessary

- Allow full air drying

- Always dry spin before use

Storage between sessions also matters:

https://tahoegrinderco.com/product-category/all-products/smoking-accessories/stash-jars/

Final Takeaway: Smoothness Is a Process, Not a Switch

A grinder doesn’t snap back to perfection the second it’s clean. Smoothness is re-earned through drying, alignment, and gentle break-in — not hacks or lubrication.

If you let the grinder reset naturally, it will feel just as good — and often better — than before cleaning.

Patience beats force every time.