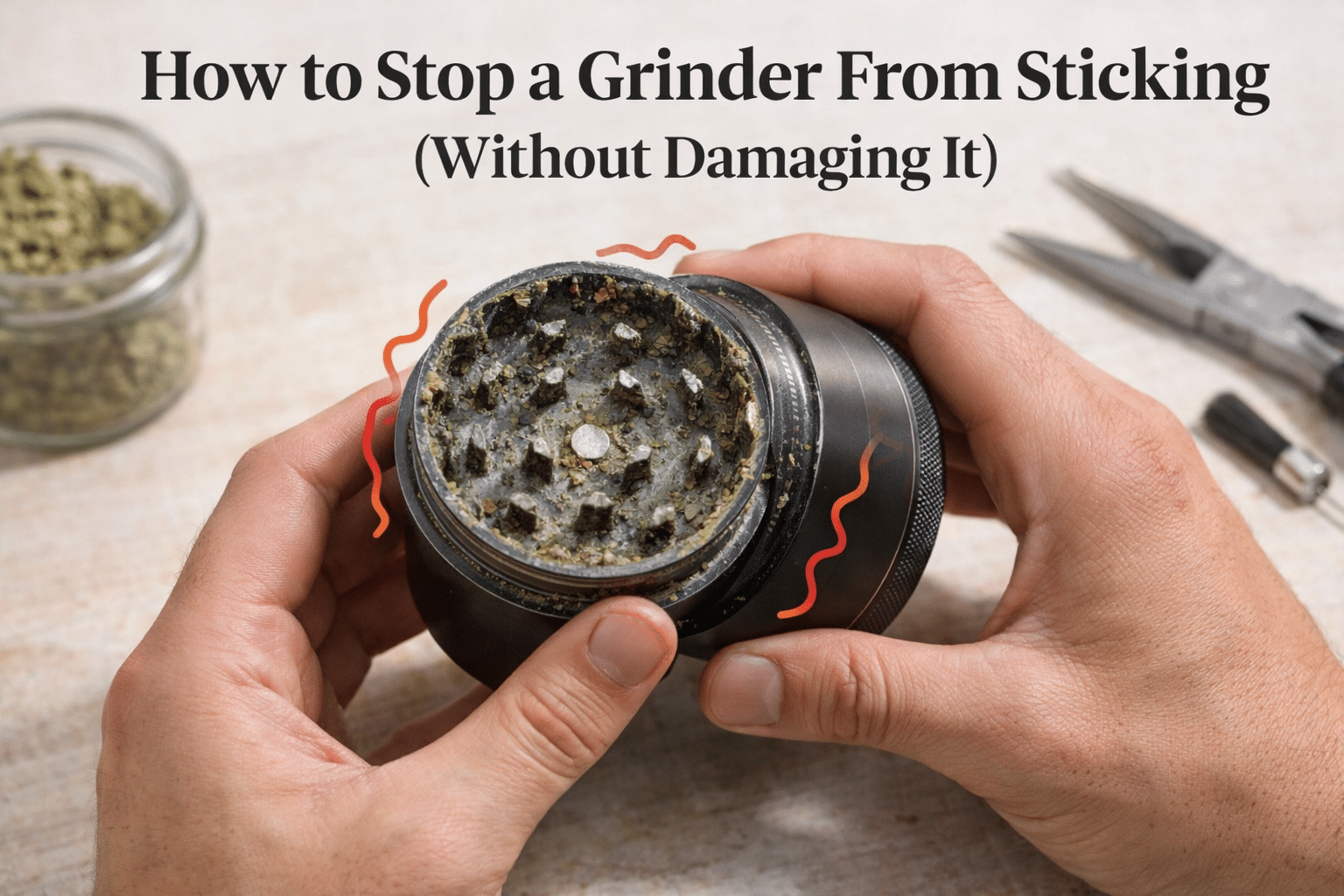

A grinder that sticks, binds, or suddenly feels hard to turn isn’t just inconvenient—it’s telling you something about friction, alignment, or resin buildup. The biggest mistake people make is trying to “muscle through” the resistance. Forcing a grinder is the fastest way to damage teeth, misalign parts, and permanently degrade performance.

The good news: most sticking problems are easy to fix—and even easier to prevent—if you address the real cause.

This guide explains why grinders stick, how to free them safely, and how to keep them turning smoothly long-term without sanding, scraping, or harsh hacks.

Why Grinders Stick in the First Place

Almost all sticking comes from one (or more) of these factors:

- Resin buildup

- Overfilling and compaction

- Surface friction from coatings or wear

- Misalignment under torque

- Foreign debris (stems, grit)

Sticky modern flower magnifies every one of these issues.

The #1 Rule: Never Force a Stuck Grinder

If you take nothing else away, take this:

Resistance is a warning, not a challenge.

Forcing rotation:

- Rounds teeth

- Smears resin deeper

- Accelerates alignment wear

- Turns a fixable problem into permanent damage

Stop, diagnose, then act.

Step-by-Step: Safely Unstick a Grinder

Step 1: Empty the Grinder Completely

Remove all flower and shake loose material out. Many grinders feel stuck simply because compacted flower is jamming the teeth.

Test it empty.

If it turns smoothly empty, the issue is load/resin—not mechanical damage.

Step 2: Check for Sudden Jams (Debris)

Look closely for:

- Stems wedged between teeth

- Seeds

- Grit or sand

- Packaging debris

If resistance appeared suddenly, debris is likely the cause. Remove gently—no prying.

Step 3: Clean the Right Way (No Damage)

What to use

- Isopropyl alcohol (90%+ for metal grinders)

- Soft brush or toothbrush

- Warm water rinse

- Full air dry

What not to do

- ❌ Scrape with metal tools

- ❌ Sand teeth

- ❌ Use knives or files

- ❌ Heat the grinder

Soak only metal parts. Avoid soaking painted, coated, or plastic grinders.

A proper clean removes resin—the #1 cause of sticking—without harming surfaces.

Step 4: Lightly Condition (Optional, Controlled)

After drying, grind a small amount of dry-to-medium flower. This lightly conditions contact surfaces and restores smooth rotation.

Do not use sticky strains immediately after cleaning.

Common Causes & Targeted Fixes

Cause 1: Resin Buildup (Most Common)

Symptoms

- Gradual increase in resistance

- “Gummy” feeling

- Worse with sticky strains

Fix

- Clean thoroughly (as above)

- Reduce load size

- Clean more frequently (light cleans beat deep cleans)

Cause 2: Overfilling

Symptoms

- Immediate resistance

- Uniform heaviness

- Grinder works fine with smaller loads

Fix

- Use less flower

- Break large buds by hand

- Grind in stages

Cause 3: Painted or Coated Surfaces Wearing

Symptoms

- Grinder gets worse after cleaning

- Rough or scratchy feel

- Visible coating wear

Fix

- None. This is permanent surface degradation.

Prevention

- Avoid painted or decorative coatings

- Use structurally treated surfaces (e.g., anodized aluminum)

Cause 4: Misalignment

Symptoms

- Grinding feels gritty even when clean

- Resistance changes by rotation angle

- Clicking or scraping

Fix

- Clean and reassemble carefully

- If sticking persists empty, alignment is compromised

Misalignment is usually end-of-life for performance.

Cause 5: Sticky Weed + Poor Technique

Symptoms

- Grinder binds only with certain strains

- Resistance spikes mid-turn

Fix

- Reduce load size

- Grind slowly

- Let flower breathe briefly before grinding

- Stop at first resistance drop

Sticky weed requires control, not force.

What NOT to Do (These Cause Permanent Damage)

- ❌ Freezing the grinder

- ❌ Boiling it

- ❌ Lubricating with oils

- ❌ Sanding teeth

- ❌ Filing surfaces

- ❌ Forcing through resistance

These “hacks” may give temporary relief but permanently ruin precision surfaces.

How to Prevent Grinder Sticking Long-Term

1. Grind Smaller Loads

Room to move = less friction.

2. Stop When Resistance Drops

Over-grinding creates dust and resin smear.

3. Clean Lightly, More Often

Regular light cleaning prevents heavy buildup.

4. Avoid Over-Humid Flower

Excess moisture accelerates sticking.

5. Use Controlled Rotation

Slow, even pressure beats speed every time.

When Sticking Means It’s Time to Replace the Grinder

Replace the grinder if:

- It sticks even when clean and empty

- Teeth no longer slice cleanly

- Rotation feels rough permanently

- Alignment has shifted

- Performance never returns

That’s not dirt—that’s wear.

Final Takeaway

A sticking grinder is almost always fixable if you don’t force it.

The key principles are simple:

- Diagnose before acting

- Remove resin, don’t fight it

- Preserve surfaces

- Respect resistance

Grinders fail when people try to overpower physics.

They last when people work with it.

Stop the sticking the right way, and your grinder will stay smooth, consistent, and predictable for years.