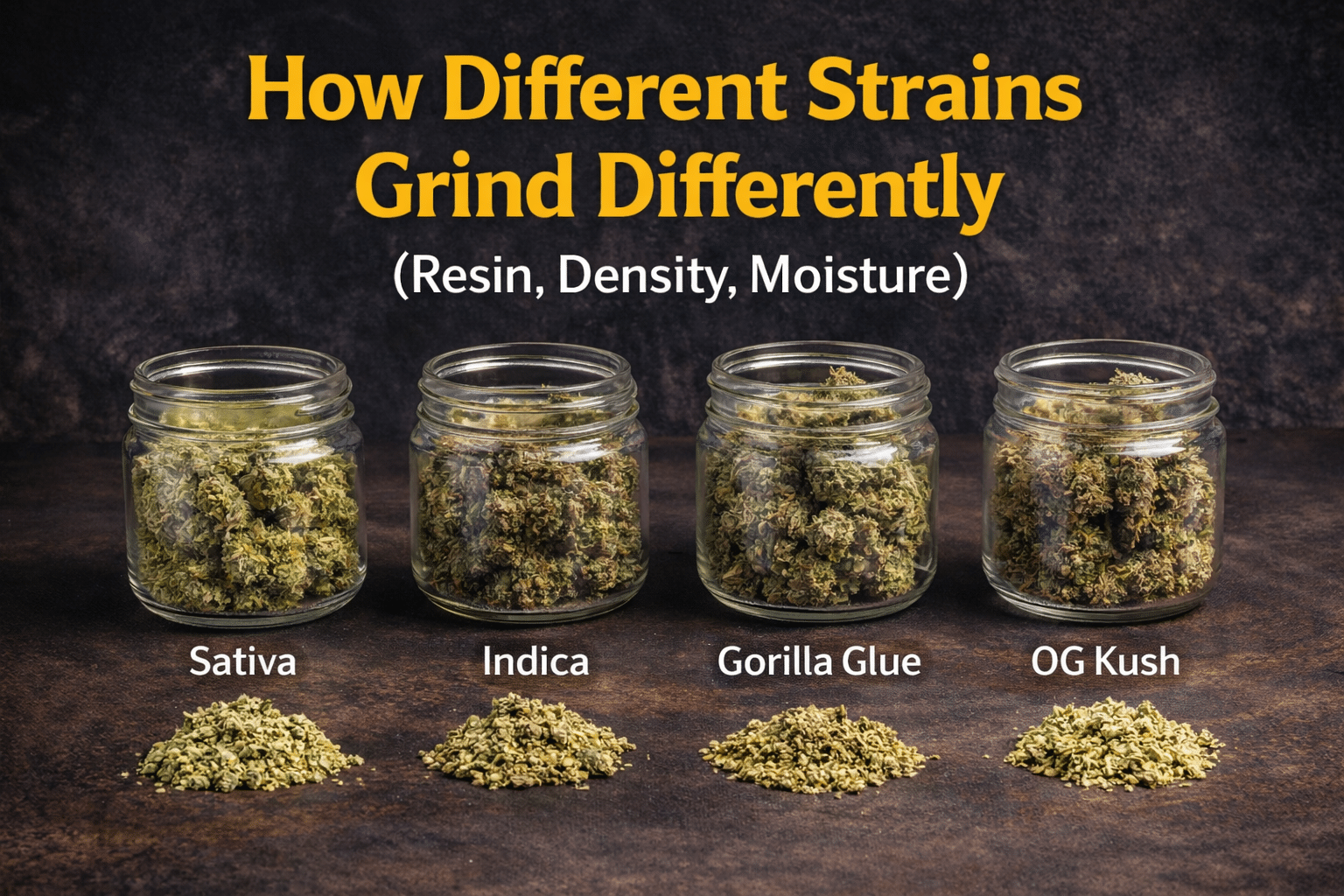

If you’ve ever wondered why one strain turns into a fluffy, perfect grind while another clogs your grinder, smears resin everywhere, or comes out uneven no matter what you do — the answer isn’t your imagination.

Different cannabis strains grind differently because they are physically different materials.

In 2026, modern cannabis genetics have pushed resin production, bud density, and terpene concentration to levels that expose these differences more clearly than ever before. Grinding weed is no longer a neutral step — it’s a mechanical interaction between plant structure, moisture content, and grinder design.

This article breaks down why strains grind differently, what’s happening at a physical level, and how resin, density, and moisture dictate grind behavior.

Grinding Is a Mechanical Process, Not Just Preparation

Grinding weed isn’t just breaking it apart. It involves:

- Shearing forces from grinder teeth

- Compression between surfaces

- Friction from rotation

- Adhesion from resin and oils

Every strain responds differently to these forces depending on its internal structure.

The Three Variables That Control Grind Behavior

Nearly all grind differences come down to three factors:

- Resin content

- Bud density

- Moisture level

Strain names matter less than how these variables combine.

Resin Content: The Biggest Difference Maker

What Resin Does During Grinding

Resin isn’t just sticky — it’s mechanically active.

High-resin strains:

- Increase friction

- Act like adhesive

- Pull material together instead of letting it separate

- Smear onto grinder surfaces

Low-resin strains behave more like dry plant matter and break cleanly.

High-Resin Strains

These strains often feel:

- Sticky to the touch

- Oily rather than crumbly

- Dense and tacky

During grinding, resin causes:

- Teeth to bind

- Flower to compress instead of shear

- Clumping inside chambers

- Reduced airflow after grinding

High-resin strains demand precise tooth geometry and surface finishes to grind cleanly.

Low-Resin Strains

Low-resin strains:

- Break apart easily

- Produce less friction

- Grind faster

But they often:

- Turn to powder quickly

- Lose terpene content

- Burn hotter and harsher

Easy grinding doesn’t always mean good performance.

Bud Density: How Structure Resists Force

Dense Buds

Dense buds:

- Resist crushing

- Require slicing rather than smashing

- Hold internal structure longer

If grinder teeth are blunt or aggressive, dense buds:

- Flatten before breaking

- Create uneven particle sizes

- Produce chunks mixed with powder

Dense strains expose poor grinder design immediately.

Airy Buds

Airy buds:

- Compress easily

- Break apart with minimal force

- Produce lighter grind output

But airy buds often:

- Grind inconsistently

- Lose structure quickly

- Burn unevenly if over-ground

Density affects how energy transfers through the bud during grinding.

Moisture: The Silent Variable

Moisture content may be the most overlooked factor in grinding behavior.

High Moisture Buds

Buds with higher moisture:

- Flex instead of snapping

- Smear resin more easily

- Clump during grinding

Grinding moist flower often leads to:

- Gummed-up teeth

- Sticky chambers

- Compacted grind output

Over-Dry Buds

Dry buds:

- Shatter easily

- Produce dust

- Lose terpene expression

Over-dry weed may grind effortlessly but:

- Burns hotter

- Loses flavor

- Wastes cannabinoids

The grind looks good — the smoke doesn’t.

The Ideal Moisture Zone for Grinding

The best grinding weed:

- Is slightly tacky

- Springs back when squeezed

- Does not crack or crumble

- Doesn’t smear resin excessively

This balance allows buds to shear cleanly instead of compressing or shattering.

How Resin, Density, and Moisture Interact

These variables don’t act independently.

Example Scenarios

- High resin + high moisture + dense bud

→ Extremely hard to grind, prone to clogging - Low resin + low moisture + airy bud

→ Easy to grind, but powdery and inefficient - Moderate resin + balanced moisture + medium density

→ Ideal grind behavior

This is why the same grinder performs differently from strain to strain.

Why Some Strains “Destroy” Cheap Grinders

Sticky, dense strains apply:

- Higher torque

- More friction

- Greater surface adhesion

Cheap grinders:

- Smash instead of slice

- Have poor surface finishes

- Lose alignment under load

These strains don’t cause the problem — they reveal it.

Tooth Geometry Determines How Strains Respond

Good grinder teeth:

- Slice flower cleanly

- Minimize compression

- Reduce resin smear

Poor tooth geometry:

- Crushes buds

- Forces resin outward

- Produces uneven grind

High-resin strains require precision slicing — not brute force.

Why Grind Output Looks Different Between Strains

Some strains produce:

- Fluffy, aerated output

- Uniform particle size

Others produce:

- Dense clumps

- Sticky strands

- Mixed chunks and powder

This isn’t random — it’s physics.

Grinding Is Strain-Specific Optimization

There is no single “perfect grind” for every strain.

Good grinders allow:

- Controlled output

- Minimal over-processing

- Predictable behavior across strain types

This adaptability is why precision grinders outperform aggressive ones.

Why Consistency Matters More Than Speed

Fast grinding feels productive, but:

- Speed increases friction

- Friction increases resin smear

- Resin smear ruins consistency

Controlled grinding preserves structure and airflow.

How Grind Differences Affect Smoking Performance

Strains that grind well:

- Burn evenly

- Maintain airflow

- Preserve terpenes

- Deliver smoother hits

Strains that grind poorly:

- Clog bowls

- Burn unevenly

- Feel harsh

- Waste THC

Grinding behavior directly affects downstream performance.

Modern Genetics Made Grinding More Important

In 2026, cannabis strains are:

- More resin-rich

- More terpene-dense

- Structurally complex

Grinding is no longer optional optimization — it’s essential preparation.

Final Takeaway

Different strains grind differently because they are physically different materials. Resin content controls adhesion, bud density controls resistance to force, and moisture determines whether flower shears cleanly or smears under pressure.

Understanding these variables explains why:

- Some strains clog grinders

- Some grind effortlessly

- Some waste weed if prepared incorrectly

Grinding isn’t just breaking weed apart — it’s managing resin, structure, and moisture in a controlled way.

When grind quality improves, everything downstream improves with it.