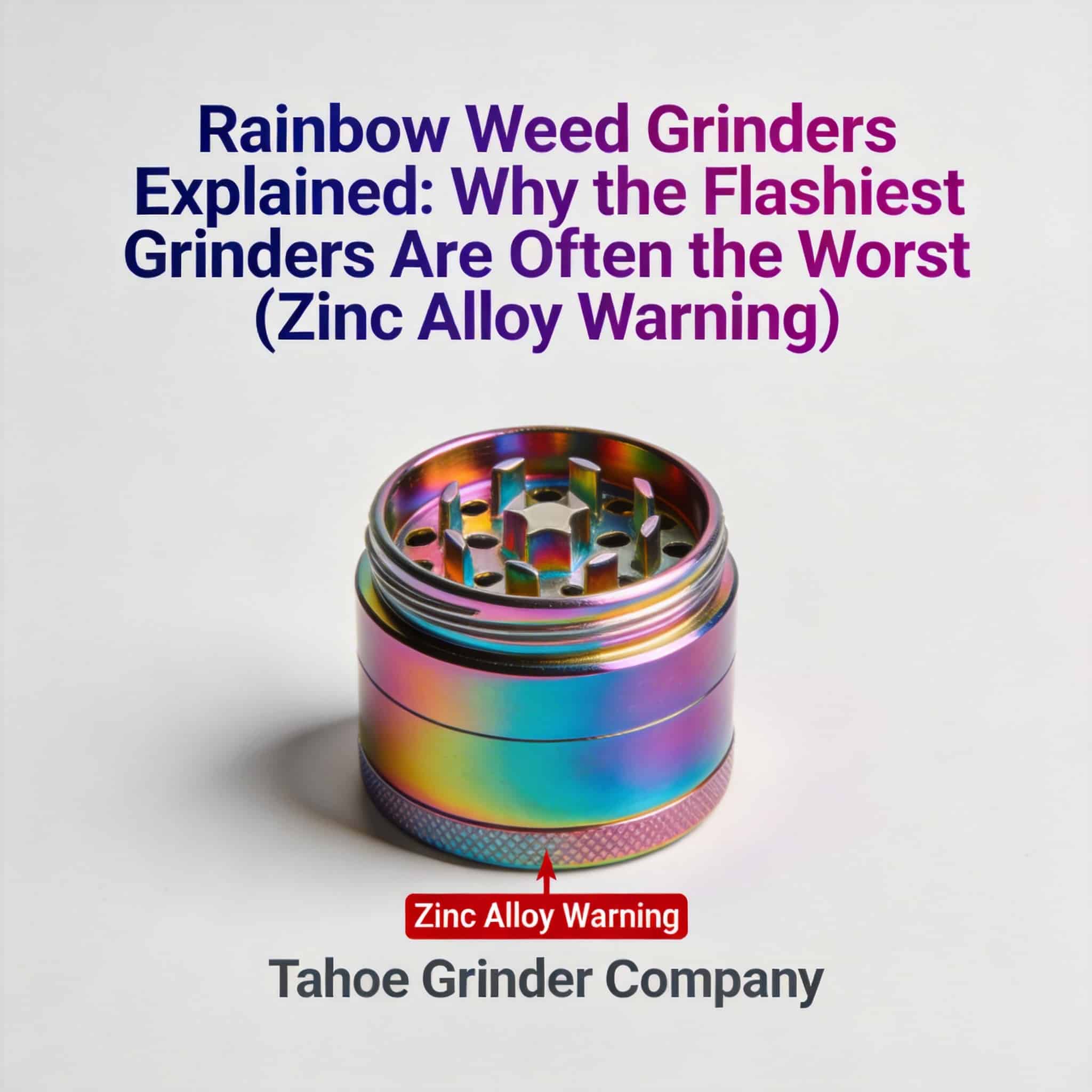

If you’ve ever seen a grinder with that flashy rainbow / oil-slick finish—purple, blue, green, gold hues shifting in the light—you’ve seen one of the biggest material problems in the weed grinder industry.

They look incredible in product photos.

They dominate Amazon listings.

They’re cheap. Heavy. Shiny.

And they are almost always zinc alloy grinders.

This article explains why rainbow-coated grinders are nearly always zinc, why that coating cannot be applied to aluminum, why these grinders flake and fail, and exactly how to spot one instantly—even without touching it.

This is not opinion. This is manufacturing reality.

What Are “Rainbow” Grinders Actually Made Of?

That iridescent, oil-slick, rainbow finish is created using PVD-style decorative coatings or electroplated color treatments that are not compatible with anodized aluminum.

Here’s the key point:

👉 That rainbow coating cannot be applied to aluminum through true anodizing.

Anodizing aluminum produces:

- Solid colors

- Matte or satin finishes

- Uniform, controlled tones

It does not produce rainbow gradients, oil-slick purples, or color-shift effects.

Those finishes require:

- Electroplating

- Decorative surface coatings

- Painted or vapor-deposited layers

And those processes are almost always applied to die-cast zinc alloy, not machined aluminum.

Why Zinc Is Used for Rainbow Grinders

Zinc is used because it makes these grinders:

- Extremely cheap to manufacture

- Easy to cast into complex shapes

- Compatible with flashy decorative coatings

Most rainbow grinders are produced by:

- Melting scrap zinc alloy

- Pouring or injecting it into molds (die-casting)

- Applying a cosmetic rainbow coating

- Shipping them by the container load

This is why they flood online marketplaces.

They are designed to sell on looks, not performance.

Why Rainbow Grinders Are the Biggest Problem in the Industry

These grinders combine three bad things at once:

- Zinc alloy base metal

- Decorative surface coating

- Die-cast manufacturing

That combination leads directly to:

- Flaking finishes

- Metal shedding

- Poor grind consistency

- Short lifespan

- Potential contamination concerns

Once the coating wears—usually quickly—you’re grinding directly against cast zinc alloy.

That’s the issue.

Why That Coating Always Fails

Rainbow coatings are not structural.

They are thin surface layers that:

- Wear under friction

- Chip on tooth edges

- Peel near threads

- Degrade during cleaning

Grinders experience constant:

- Metal-on-metal contact

- Pressure

- Resin abrasion

Decorative coatings are simply not built for that.

This is why you’ll often see:

- Purple flakes inside the grinder

- Silver-gray metal underneath

- Discoloration around teeth

That’s coating failure—by design.

How to Spot a Zinc Grinder Instantly (Even in Photos)

You can identify a zinc grinder without touching it if you know what to look for.

🔍 Look at the Sides of the Teeth

Zinc grinder teeth:

- Extremely smooth sidewalls

- Rounded, soft-looking edges

- No visible machining marks

Because they are cast, not cut.

Machined aluminum teeth:

- Visible machining lines

- Sharp, defined geometry

- Crisp edges

Casting cannot replicate machining precision.

🔍 Look at the Base of the Teeth

This is the biggest giveaway.

On zinc grinders, around the base of the teeth you’ll often see:

- A grainy texture

- A sandy or pebbled appearance

- A surface that looks like beach sand

That texture comes from the casting mold itself.

Whether the mold is:

- Sand-cast

- Sandblasted

- Textured steel

The surface texture transfers directly into the part.

👉 Machined aluminum does not have this texture.

If it looks like sand around the tooth base, it’s cast zinc.

🔍 Look for Perfect Symmetry (Too Perfect)

Zinc grinders are cast in two mold halves.

That means:

- One side mirrors the other

- Identical imperfections appear on both halves

- Seam lines may be visible

Machined grinders do not mirror imperfections.

Why Zinc Grinders Feel Heavy but Perform Poorly

Zinc is dense.

That’s why these grinders feel “solid” when you pick them up.

But density ≠ quality.

Zinc:

- Is softer than aluminum

- Deforms more easily

- Chips instead of wearing evenly

- Loses alignment over time

Heavy doesn’t mean durable.

Precision does.

Why Aluminum Grinders Don’t Use Rainbow Coatings

Proper aluminum grinders use anodizing, not paint or plating.

Anodizing:

- Becomes part of the aluminum surface

- Cannot flake or peel

- Is food-safe and inert

- Maintains tolerances

That’s why high-quality grinders stick to solid colors and satin finishes:

https://tahoegrinderco.com/product-category/all-products/2-piece-weed-grinders/

And why rainbow finishes are a red flag.

Why These Grinders Dominate Amazon Listings

Rainbow grinders win on:

- Clicks

- Photos

- First impressions

They lose on:

- Performance

- Longevity

- Safety

- Consistency

They are impulse buys, not tools.

Once used with real flower—especially sticky strains—they fail fast.

What Happens When the Coating Starts Flaking

Once flaking begins:

- Metal is exposed

- Teeth wear accelerates

- Grinding consistency collapses

- Cleaning becomes risky

This is why many users replace these grinders within months.

Compare that to properly machined grinders designed for long-term use:

https://tahoegrinderco.com/product-category/all-products/3-piece-weed-grinders/

Why We Don’t Make Rainbow Grinders

At Tahoe Grinder Co., we don’t use:

- Zinc alloy

- Die-cast parts

- Decorative coatings

We use precision-machined aluminum with food-grade anodized finishes because:

- The material is controlled

- The finish cannot flake

- The grind stays consistent

- The tool lasts

That philosophy applies across our lineup:

https://tahoegrinderco.com/product-category/all-products/4-piece-weed-grinders/

The Easiest Rule to Remember

If a grinder:

- Has a rainbow / oil-slick finish

- Looks purple-blue-green in photos

- Is unusually cheap

- Shows sandy texture near teeth

👉 It is almost certainly cast zinc.

And it should be avoided.

Final Takeaway: Flashy Is Not Functional

Rainbow grinders are designed to sell in photos—not to grind well.

They:

- Use the cheapest metal

- Rely on cosmetic coatings

- Hide casting flaws

- Fail under real use

A grinder should be treated like a tool, not jewelry.

If you want consistency, safety, and long-term performance, avoid flashy finishes and focus on material, machining, and surface treatment.

That’s the difference between something that looks good for a week—and something that works for years:

https://tahoegrinderco.com/product-category/all-products/