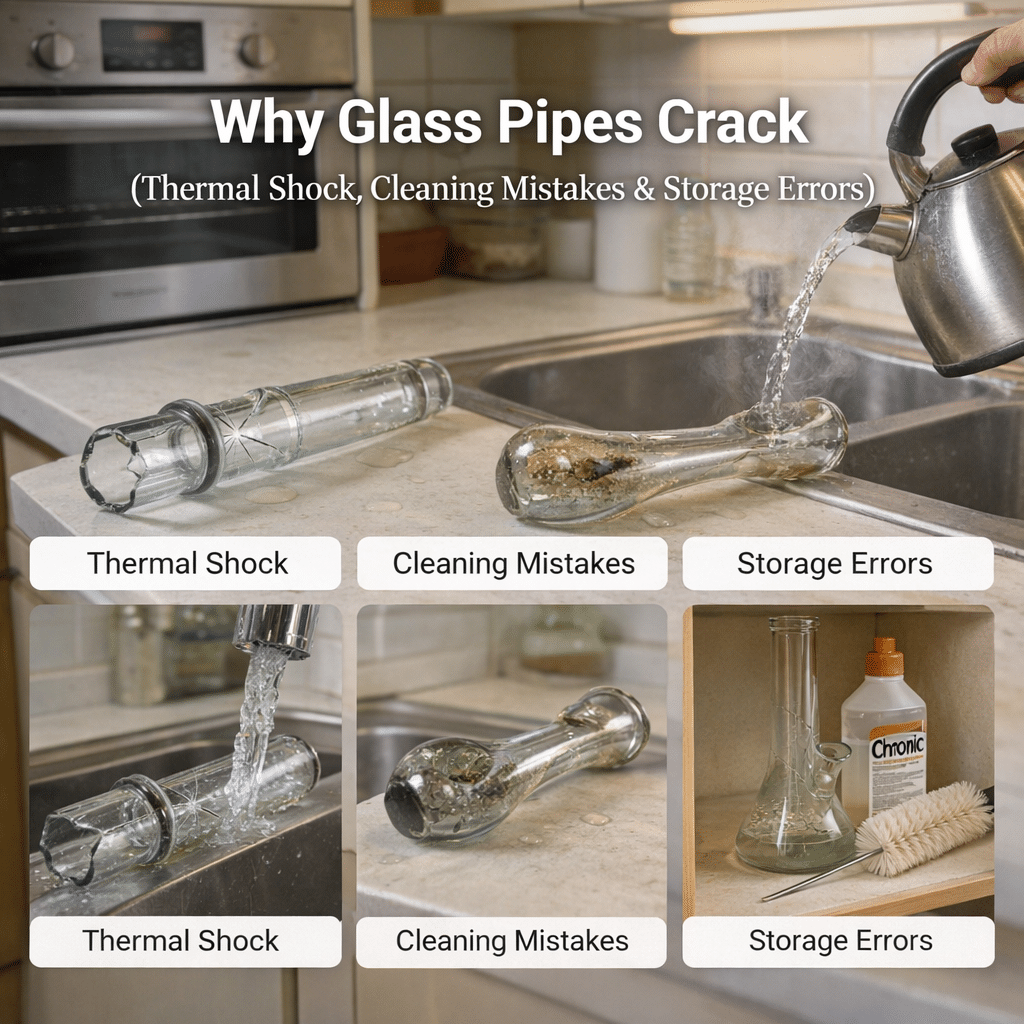

(Thermal Shock, Cleaning Mistakes & Storage Errors)

When a glass pipe cracks, most people assume it was “cheap glass” or bad luck. In reality, glass pipes almost always crack because of thermal stress, not impact. Even high-quality borosilicate glass can fail if it’s exposed to the wrong conditions.

Cracking isn’t random. It’s mechanical and predictable.

This guide explains why glass pipes crack, the specific mistakes that cause it, and how to prevent cracks permanently—without babying your pipe.

The Real Cause of Most Cracks: Thermal Shock

What Thermal Shock Actually Is

Thermal shock occurs when glass experiences rapid, uneven temperature change.

Glass expands when heated and contracts when cooled. If different parts of the pipe change temperature at different rates, internal stress builds. When that stress exceeds the glass’s tolerance, the glass cracks.

This happens even without impact.

Why Pipes Are Vulnerable to Thermal Shock

Glass pipes experience extreme temperature gradients:

- Bowl area heats rapidly from flame

- Stem and mouthpiece remain cool

- Cleaning introduces cold or hot water suddenly

- Storage environments change temperature

The bigger the temperature difference, the higher the stress.

Borosilicate vs Soft Glass (Important Context)

Borosilicate glass:

- Has low thermal expansion

- Resists thermal shock far better

- Tolerates repeated heating and cooling

Soft (soda-lime) glass:

- Expands more when heated

- Is far more crack-prone

- Fails faster under repeated heat cycles

Borosilicate reduces risk—it does not eliminate it.

The Most Common Ways Glass Pipes Crack

1. Cold Water on a Hot Pipe (Most Common)

This is the #1 pipe killer.

What happens:

- Bowl is hot

- Cold water hits exterior or interior

- Outer glass contracts instantly

- Inner glass is still expanded

- Stress fractures form

Even borosilicate can crack this way.

Rule: Never rinse a hot pipe.

2. Boiling or Freezing Without Gradual Transition

Thermal shock works both directions.

Common mistakes:

- Dropping a cold pipe into boiling water

- Taking a pipe from freezer to flame

- Placing a hot pipe on cold surfaces

Glass needs gradual temperature change.

3. Cleaning Too Aggressively

Cracking isn’t always immediate.

Aggressive cleaning causes:

- Microfractures

- Stress points

- Weak zones that crack later under heat

Common mistakes:

- Scraping with metal tools

- Forcing brushes into tight areas

- Using abrasive materials

- Repeated boiling without cooldown

The pipe survives cleaning—then cracks days later during use.

4. Resin Hardening and Uneven Heating

Resin isn’t just sticky—it affects heat flow.

As resin builds up:

- Heat distributes unevenly

- Hot spots form

- Localized expansion increases

- Stress concentrates in one area

This is why dirty pipes crack more often than clean ones.

5. Poor Storage (Slow, Silent Damage)

Storage issues cause delayed cracks.

Risky storage conditions:

- Hot cars

- Window sills

- Near heaters

- Unpadded bags

- Loose drawers

Repeated temperature cycling weakens glass over time, even without visible damage.

6. Impact Isn’t Always Obvious

Tiny impacts matter.

Light knocks:

- Create microfractures

- Don’t cause immediate breakage

- Fail later under heat stress

That “mystery crack” often started with a minor bump days earlier.

Why Pipes Often Crack at the Bowl or Joint

Certain areas crack first because they experience the most stress.

High-risk zones:

- Bowl base

- Bowl-to-stem transition

- Carb hole area

- Decorative weld points

These areas:

- Heat fastest

- Cool unevenly

- Experience structural transitions

This isn’t coincidence—it’s stress concentration.

Why Cracks Sometimes Appear “Out of Nowhere”

Glass cracks don’t always happen instantly.

The timeline:

- Stress or microfracture forms

- Pipe survives multiple uses

- Stress accumulates

- Crack suddenly propagates

The cause happened earlier—the crack just finished later.

How to Prevent Glass Pipes From Cracking

1. Let Pipes Cool Before Cleaning

Always wait until the pipe is room temperature before rinsing.

2. Avoid Temperature Extremes

No freezer tricks. No boiling shortcuts. No cold countertops.

3. Clean Gently, Not Aggressively

Soak. Shake. Rinse. Repeat.

Don’t scrape or force tools.

4. Clean Regularly

Clean pipes heat more evenly than resin-coated ones.

5. Store Smart

- Room temperature

- Padded containers

- Away from heat and sunlight

- Not loose in bags or cars

6. Use Controlled Flame

Torching the bowl concentrates heat fast. Gentle flame control reduces stress.

Myths About Glass Pipe Cracking

“Thicker Glass Won’t Crack”

Thickness helps with impact, not thermal shock.

“Only Cheap Glass Cracks”

False. All glass cracks if stressed improperly.

“Cracks Mean Bad Manufacturing”

Sometimes—but most cracks are user-induced stress failures.

When a Cracked Pipe Is No Longer Safe

Stop using a pipe if:

- Cracks extend into the airway

- Cracks grow after use

- Edges feel sharp

- Airflow changes suddenly

Cracked glass can shed shards. It’s not worth the risk.

Final Takeaway

Glass pipes don’t crack randomly. They crack because of thermal shock, stress concentration, and time.

The biggest enemies are:

- Rapid temperature changes

- Aggressive cleaning

- Poor storage

- Resin buildup

- Hidden microfractures

Treat glass with gradual transitions and consistent care, and even daily-use pipes can last years.

Most cracked pipes didn’t fail suddenly—they were stressed slowly until physics finally won.

Once you understand why glass cracks, preventing it becomes simple—and predictable.