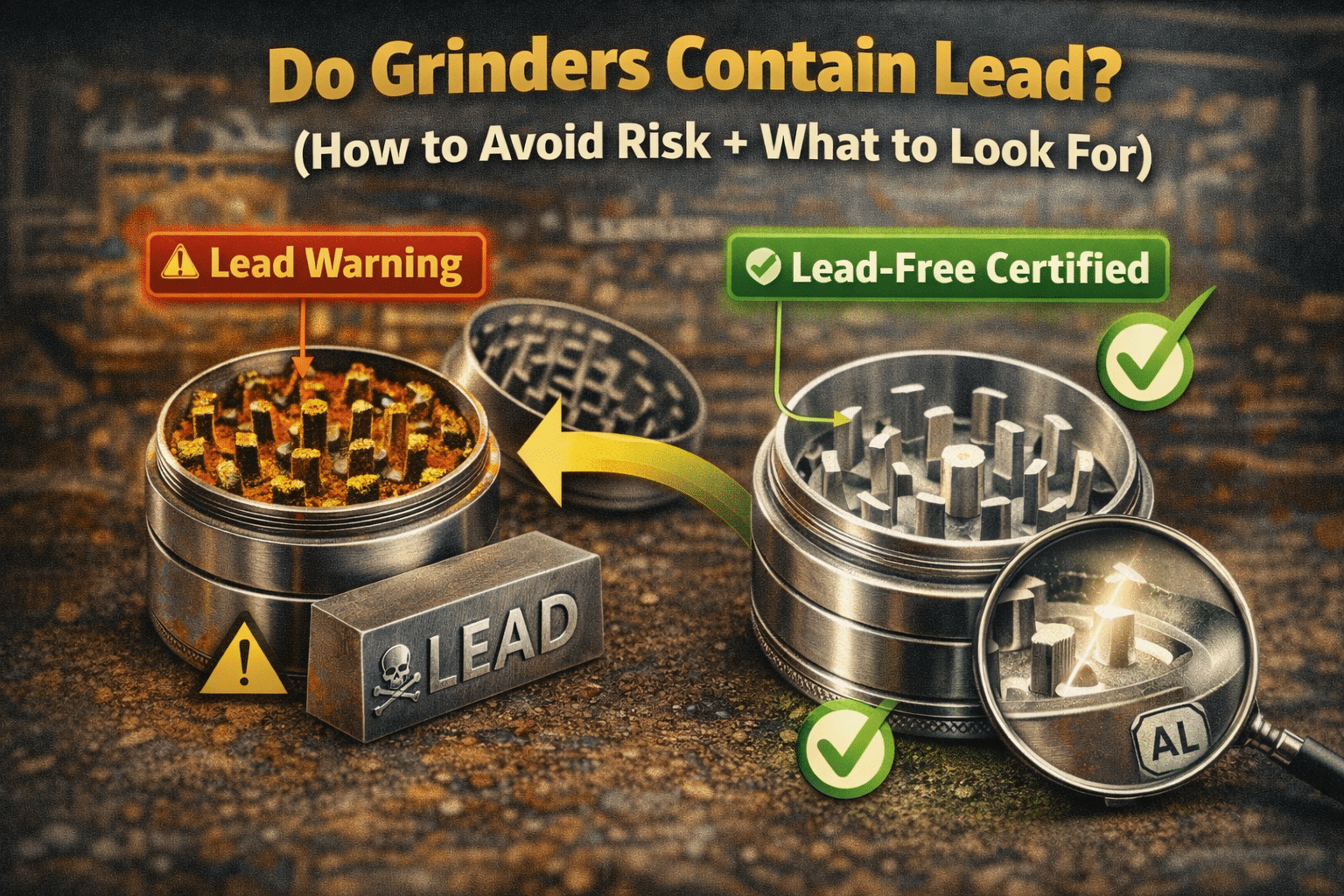

Short version? Yes—some grinders absolutely can contain lead.

But it’s not random, and it’s not unavoidable. Lead shows up for specific reasons, in specific types of grinders. Once you know what to look for, avoiding it is straightforward.

This guide breaks down where lead comes from, which grinders are highest risk, and how to spot safe vs sketchy metal before you ever grind flower.

Why Lead Ends Up in Weed Grinders at All

Lead doesn’t magically appear in grinders. It gets there through material choice and manufacturing shortcuts.

The biggest culprit by far is:

❌ Zinc Alloy (Die-Cast Metal)

Cheap grinders are often made from zinc alloy (sometimes called “pot metal” or Zamak). Zinc itself isn’t the main issue—the problem is how it’s sourced and processed.

- Zinc alloy is commonly made from recycled scrap

- Scrap zinc can contain lead, cadmium, mercury, and other heavy metals

- Die-casting melts everything together

- There’s no practical way to fully remove contaminants at low cost

Once cast, whatever was in the melt is now in the grinder.

That’s the risk.

The Biggest Red Flag: Rainbow / Oil-Slick Grinders

If you’ve ever seen those flashy rainbow grinders—usually purple with green, blue, and gold tones—this part matters.

Those grinders are almost always zinc alloy.

Why?

- That coating cannot be applied to aluminum

- It’s commonly used on die-cast zinc

- Zinc accepts that electroplated “oil slick” finish easily

These are the grinders most associated with:

- Flaking coatings

- Metallic residue

- Unknown alloy composition

They look amazing in Amazon photos.

They’re also the highest-risk grinders in the market.

How Lead Exposure Actually Happens

Important clarification:

Lead isn’t “leaching” like a liquid.

The risk comes from:

- Micro-wear at the teeth

- Abrasion during grinding

- Coating or alloy particles mixing with flower

- Inhaling or ingesting trace metal over time

You don’t taste it. You don’t see it.

It accumulates slowly.

That’s why this matters.

How to Spot a High-Risk Grinder (Visual Inspection)

You can identify risky grinders without tools if you know what to look for.

🔍 Look at the Teeth

Zinc grinders:

- Extremely smooth tooth sides

- No visible machining marks

- Rounded edges instead of sharp cuts

Machined aluminum grinders:

- Clear tool paths

- Defined cutting geometry

- Crisp edges

🔍 Look at the Base of the Teeth

This is the giveaway.

On zinc grinders, you’ll often see:

- A grainy, sandy texture

- Slightly uneven surface

- Identical texture on both halves (from mold casting)

That sand-like appearance comes from the casting process itself.

Machined aluminum does not look like that.

🔍 Look at the Finish

High-risk finishes:

- Rainbow / oil-slick

- Painted metal

- Thick coatings that chip or flake

Lower-risk finishes:

- Bare metal

- Type II or Type III anodizing

- Matte or satin aluminum tones

Materials That Do Not Contain Lead (When Done Right)

✅ CNC-Machined Aluminum (6061-T6)

- Solid billet material

- Known alloy composition

- No casting

- No scrap melting

- No mystery metals

This is why premium grinders stick to aluminum:

https://tahoegrinderco.com/product-category/all-products/

✅ Stainless Steel (Rare, but Safe)

- Heavy

- Expensive

- Difficult to machine

- Almost never used cheaply

Safe—but uncommon in grinders.

⚠️ Titanium (Generally Safe, but Not Perfect)

Titanium itself doesn’t contain lead.

But titanium grinders can still suffer from:

- Resin adhesion

- Simplified tooth geometry

- High cost with limited performance gains

Material-safe, but not automatically “better.”

Why Coatings Matter as Much as Base Metal

Even safe metal can become unsafe if the coating is wrong.

Avoid:

- Painted grinders

- Unknown “ceramic” coatings without specs

- Decorative finishes without wear testing

Prefer:

- Food-grade anodized aluminum

- No-fade, non-painted surfaces

- Coatings that become part of the metal, not a layer on top

This is why many premium grinders use anodizing instead of paint:

https://tahoegrinderco.com/product-category/all-products/2-piece-weed-grinders/

Why Reputable Brands Avoid Zinc Entirely

Using zinc is tempting because:

- It’s cheap

- It casts fast

- Tooling costs are low

- Margins are huge

Brands that care about long-term use avoid it—even though it costs more to do so.

That’s why companies like Tahoe Grinder Company do not use zinc alloy in any grinder:

https://tahoegrinderco.com/product-category/all-products/3-piece-weed-grinders/

https://tahoegrinderco.com/product-category/all-products/4-piece-weed-grinders/

You can’t “test out” lead risk after the fact. You avoid it at the material level.

Do All Cheap Grinders Contain Lead?

Not necessarily—but cheap + zinc + casting is where the risk lives.

A low-cost aluminum grinder can be safe.

A flashy zinc grinder is the danger zone.

Price alone isn’t the issue.

Material transparency is.

Quick Checklist: How to Avoid Lead in a Grinder

Before buying, ask:

- Is it CNC-machined or cast?

- Is the material specified (not just “metal”)?

- Is the finish anodized or painted?

- Do the teeth show machining marks?

- Is the grinder suspiciously flashy for the price?

If those answers aren’t clear—walk away.

Final Takeaway

Yes, some grinders can contain lead—especially zinc alloy, die-cast, rainbow-finish grinders.

But avoiding risk isn’t complicated:

- Choose machined aluminum or stainless

- Avoid zinc alloy and decorative coatings

- Buy from brands that disclose materials clearly

Your grinder isn’t just an accessory.

It’s part of your consumption path.

Treat it like the tool it is.