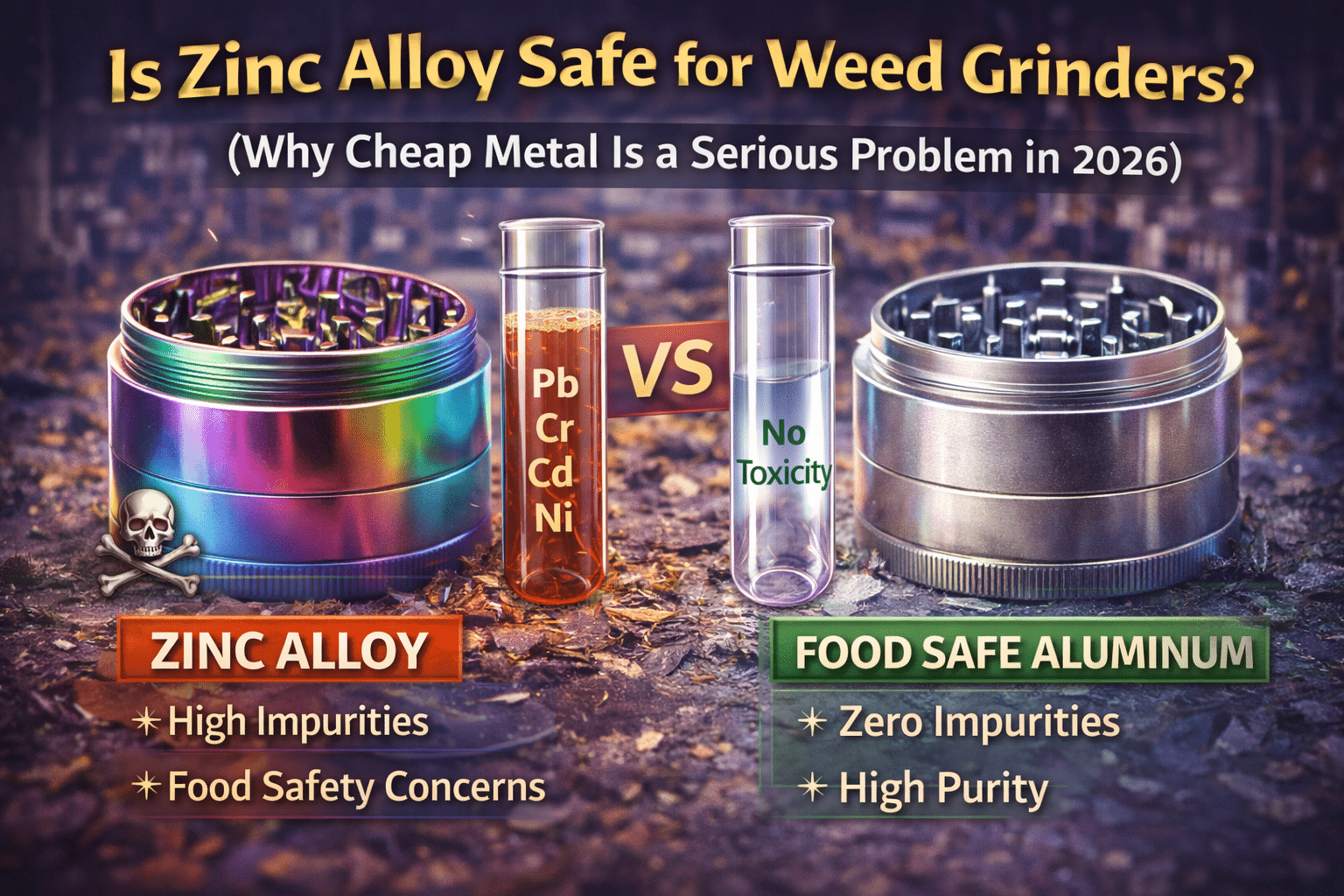

Zinc alloy is one of the worst possible materials for a weed grinder — and in 2026, it’s still everywhere.

If you’ve ever used a grinder that felt heavy but cheap, dulled quickly, chipped, squeaked, or left gray residue behind, there’s a good chance it was made from die-cast zinc alloy. These grinders dominate the low-cost end of the market because zinc is easy to manufacture, fast to scale, and extremely cheap to source.

At Tahoe Grinder Co., we intentionally do not use zinc alloy in any grinder we produce — and this article explains exactly why.

This isn’t marketing fluff. This is about materials science, manufacturing reality, and health safety.

What Is Zinc Alloy, Really?

Zinc alloy grinders are typically made using die-cast manufacturing, where molten metal is injected into molds and cooled rapidly. This process is fast and inexpensive, which makes it attractive for mass-produced accessories.

But here’s the problem:

Zinc alloy is rarely pure.

It’s often made from mixed or recycled scrap zinc, which may include trace amounts of:

- Lead

- Mercury

- Cadmium

- Other heavy metals

Unless extremely strict material controls are used (which cheap grinder manufacturers do not use), these contaminants can remain in the finished product.

That’s unacceptable for something designed to grind material you inhale.

Why Zinc Alloy Is So Common in Cheap Grinders

Zinc isn’t used because it’s good — it’s used because it’s easy.

Zinc alloy grinders are popular with low-end manufacturers because:

- Die-casting is fast

- Tooling is cheap

- Scrap zinc is abundant

- Minimal machining is required

- Little to no finishing is needed

This allows companies to flood the market with grinders at extremely low prices.

But cheap manufacturing shortcuts come with real consequences.

The Hidden Contamination Risk

Zinc alloy itself is not the only issue — what’s mixed into it is.

Because zinc is often sourced from recycled scrap:

- Composition can vary wildly

- Heavy metal contamination is difficult to fully control

- Quality assurance is inconsistent or nonexistent

Unlike regulated food or medical manufacturing, most zinc grinders are produced without third-party material certification.

That means you have no way to verify what’s actually in the metal.

Why This Matters for Weed Grinders Specifically

A weed grinder is not a decorative object.

It:

- Applies friction

- Generates fine particles

- Directly contacts plant material you combust or vaporize

Every grind creates metal-to-metal abrasion.

In zinc alloy grinders, this abrasion can:

- Release microscopic metal particles

- Wear through coatings

- Expose raw alloy underneath

Once that happens, contamination risk increases dramatically.

Why Zinc Grinders Chip, Flake, and Fail

Zinc alloy is soft and brittle compared to properly machined aluminum.

Common zinc grinder failures include:

- Teeth chipping or bending

- Threads stripping

- Coatings flaking off

- Excessive wear in high-contact areas

This isn’t bad luck — it’s inherent to the material.

By contrast, precision-machined grinders maintain tolerances and resist deformation:

https://tahoegrinderco.com/product-category/all-products/2-piece-weed-grinders/

Coatings Don’t Fix Zinc — They Hide It

Many zinc grinders are painted, powder-coated, or “non-stick” coated.

That creates two additional problems:

- The coating can wear off

- Once worn, raw zinc alloy is exposed

Painted coatings are not structural. They are cosmetic barriers that degrade under friction, heat, and cleaning.

When coatings fail, users are grinding directly against unknown metal composition.

Why Zinc Is a Red Flag in Grinder Manufacturing

If a grinder is:

- Very cheap

- Heavy but poorly balanced

- Cast instead of machined

- Painted instead of anodized

It is almost certainly zinc alloy.

That’s why zinc grinders dominate novelty shops and bulk import listings — not premium manufacturers.

The Aluminum Alternative: Why Material Choice Matters

At Tahoe Grinder Co., we use precision-machined aluminum with a food-grade, no-fade anodized coating.

Why aluminum?

Because aluminum:

- Is lightweight yet strong

- Machines cleanly

- Holds tight tolerances

- Does not chip or flake like zinc

- Can be properly anodized instead of painted

Aluminum grinders maintain consistency over thousands of uses:

https://tahoegrinderco.com/product-category/all-products/3-piece-weed-grinders/

What Anodizing Actually Does (And Why It’s Safer)

Anodizing is not paint.

It is an electrochemical process that:

- Converts the surface of aluminum into a hardened oxide layer

- Bonds at the molecular level

- Does not peel, flake, or chip

- Is inert and food-safe

This creates a durable surface that resists wear while protecting the base metal underneath.

That’s why anodized aluminum is widely used in:

- Medical tools

- Food equipment

- Aerospace components

And why it’s the gold standard for grinders.

Why Zinc Cannot Be Anodized

Zinc alloy cannot be anodized the way aluminum can.

Instead, manufacturers rely on:

- Paint

- Powder coat

- Non-stick sprays

All of which degrade over time.

Once degraded, zinc is exposed — and that’s when problems start.

Long-Term Safety vs Short-Term Cost

Zinc grinders are cheap upfront — and expensive long-term.

They:

- Wear faster

- Require replacement

- Lose performance

- Raise safety concerns

High-quality aluminum grinders last for years:

https://tahoegrinderco.com/product-category/all-products/4-piece-weed-grinders/

Why We Don’t Use Zinc at Tahoe Grinder Co.

We do not use zinc alloy in any grinder because:

- Material purity cannot be guaranteed

- Die-cast tolerances are inconsistent

- Coatings fail under real use

- Health risk is unnecessary

Instead, we invest in:

- Precision machining

- Controlled aluminum sourcing

- Food-grade anodized finishes

- Tight quality control

This applies across our entire grinder lineup:

https://tahoegrinderco.com/product-category/all-products/square-grinders/

Zinc Grinders vs Aluminum Grinders: The Bottom Line

| Feature | Zinc Alloy | Anodized Aluminum |

|---|---|---|

| Manufacturing | Die-cast | CNC machined |

| Purity | Inconsistent | Controlled |

| Coating | Paint / spray | Integrated anodizing |

| Wear resistance | Poor | Excellent |

| Particle shedding | Likely | Minimal |

| Longevity | Short | Long |

Final Verdict: Zinc Is the Wrong Material

In 2026, there is no good reason to use zinc alloy in a weed grinder.

It is cheap, fast, and profitable for manufacturers — but it sacrifices:

- Precision

- Durability

- Safety

A grinder should behave like a tool, not a novelty.

That’s why we build grinders the hard way — from food-grade anodized aluminum, machined with intention, and designed to last.

When it comes to something you use every day — and inhale from — material choice matters.