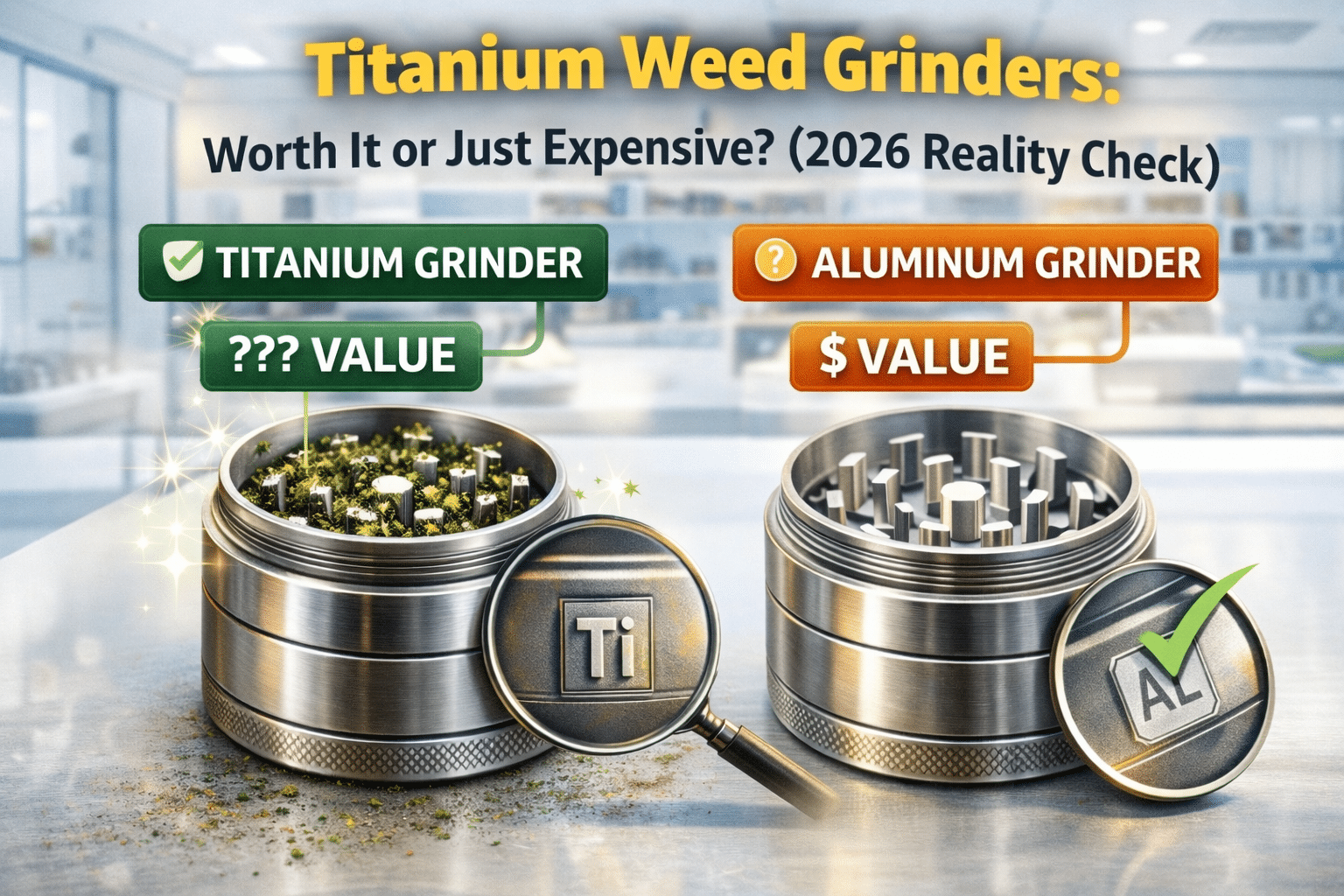

Titanium weed grinders sit at the top of the price ladder. They’re often marketed as indestructible, medical-grade, or the ultimate grinder material. And on paper, titanium sounds unbeatable—stronger than steel, lighter than steel, corrosion-proof, aerospace-approved, the whole legend.

But here’s the real question that matters in 2026:

👉 Does titanium actually make a better weed grinder—or just a more expensive one?

Let’s strip away the hype and look at titanium grinders through the same lens engineers use: material behavior, machining reality, grind performance, and long-term usability.

Why Titanium Sounds So Appealing

Titanium has a reputation problem—in a good way.

People associate titanium with:

- Aircraft

- Medical implants

- Space hardware

- Extreme durability

All of that is true. Titanium is an incredible material when the application actually needs it.

The mistake is assuming that because titanium is impressive, it’s automatically better for everything—including grinders.

What Titanium Actually Does Well

Let’s give titanium its credit first.

✅ Extreme Strength-to-Weight Ratio

Titanium is incredibly strong for its weight. It doesn’t bend easily and resists deformation extremely well.

✅ Corrosion Resistance

Titanium does not rust, oxidize, or corrode in normal environments. Moisture and resin don’t bother it.

✅ Long-Term Structural Stability

Once machined correctly, titanium holds its shape essentially forever.

From a pure durability standpoint, titanium is excellent.

Where Titanium Starts to Fall Apart for Grinders

Now for the part marketing doesn’t like to talk about.

❌ Titanium Is Hard to Machine (And That Matters)

Titanium is notoriously difficult to machine:

- It wears cutting tools rapidly

- It generates heat

- It resists clean shearing

As a result, most titanium grinders:

- Have simpler tooth geometry

- Avoid aggressive cutting profiles

- Sacrifice grind finesse for manufacturability

A grinder isn’t just a block of metal—it’s a cutting tool. Tooth geometry matters more than raw strength.

❌ Titanium Is “Sticky” at the Surface Level

Titanium has higher surface friction than anodized aluminum.

In grinder use, this means:

- Resin adheres more aggressively

- Sticky strains bind faster

- Cleaning is needed more often

This surprises a lot of people.

Titanium resists corrosion—but it does not resist resin adhesion particularly well.

❌ Overkill Is Still Overkill

Weed grinders don’t experience:

- Structural load

- Impact stress

- Tensile failure

They experience:

- Rotational friction

- Resin abrasion

- Alignment sensitivity

Titanium’s biggest strengths solve problems grinders don’t actually have.

Grind Quality: Titanium vs Aluminum

This is where premium aluminum grinders quietly outperform titanium.

Precision-Machined Aluminum Advantages

- Cleaner tooth profiles

- Better cutting geometry

- More consistent particle size

- Smoother rotation

This is why many daily users prefer well-designed aluminum grinders:

https://tahoegrinderco.com/product-category/all-products/

Titanium grinders often feel:

- Extremely solid

- Slightly harsher during grinding

- Less forgiving with sticky flower

Titanium vs Anodized Aluminum (The Real Comparison)

| Feature | Titanium | Anodized Aluminum |

|---|---|---|

| Strength | Extreme | More than sufficient |

| Weight | Light | Light |

| Machinability | Poor | Excellent |

| Tooth precision | Limited | Excellent |

| Resin behavior | Sticky | Balanced |

| Cost | Very high | Reasonable |

| Performance gain | Marginal | High |

For grinders, aluminum hits the performance sweet spot.

Why Titanium Grinders Cost So Much

Titanium grinders are expensive because:

- Raw material is costly

- Tooling wear is high

- Machining time is long

- Scrap rates are higher

You’re paying for manufacturing difficulty—not necessarily better grind results.

That doesn’t make them bad. It just makes them niche.

When a Titanium Grinder Does Make Sense

Titanium grinders can make sense if:

- You want maximum durability regardless of cost

- You value material purity above grind finesse

- You prefer a minimalist, brute-force design

- You enjoy owning overbuilt tools

For most users, though, that doesn’t translate into better sessions.

Titanium vs Cheap Metals (Important Distinction)

One thing titanium does beat decisively is:

- Zinc alloy

- Cast metals

- Painted or plated grinders

Titanium is real metal with real specs—unlike cheap die-cast alternatives.

But so is properly machined aluminum:

https://tahoegrinderco.com/product-category/all-products/2-piece-weed-grinders/

https://tahoegrinderco.com/product-category/all-products/3-piece-weed-grinders/

Why Many Premium Brands Stick With Aluminum

This isn’t about cutting corners.

Aluminum is chosen because:

- It machines beautifully

- It allows complex tooth geometry

- It holds tight tolerances

- It pairs perfectly with anodizing

- It delivers consistent grind performance

That’s why aluminum dominates high-quality grinders—even in 2026:

https://tahoegrinderco.com/product-category/all-products/4-piece-weed-grinders/

The “Medical Grade” Myth

You’ll often see titanium grinders marketed as medical grade.

Here’s the truth:

- Titanium can be medical-grade

- That does not make the grinder medical-grade

- Medical devices require controlled manufacturing, not just material choice

Slapping “medical” on titanium doesn’t change grinder performance.

Final Verdict: Titanium Is Impressive—but Mostly Overkill

Titanium weed grinders are:

- Extremely durable

- Well-made when done properly

- Technically impressive

But they are not automatically better grinders.

For actual use—daily grinding, sticky strains, smooth rotation, consistent output—precision-machined anodized aluminum still wins.

Titanium is a flex.

Aluminum is a tool.

And when it comes to grinders, tools matter more than trophies.