If you’ve been shopping for a high-quality weed grinder and seen 6061-T6 aluminum mentioned, that’s not marketing fluff — that’s an actual engineering material specification. Unlike vague phrases like “aircraft grade,” 6061-T6 tells you exactly what the metal is, how it behaves, and why manufacturers who care about performance choose it.

This article breaks down what 6061-T6 aluminum really is, why it outperforms cheaper metals in grinders, and why it’s the backbone of premium grinder manufacturing in 2026.

What “6061-T6” Actually Means

6061 refers to a specific aluminum alloy composition.

T6 refers to the heat-treatment condition.

Together, they define a metal with predictable strength, machinability, and long-term stability.

The 6061 Alloy (Composition Basics)

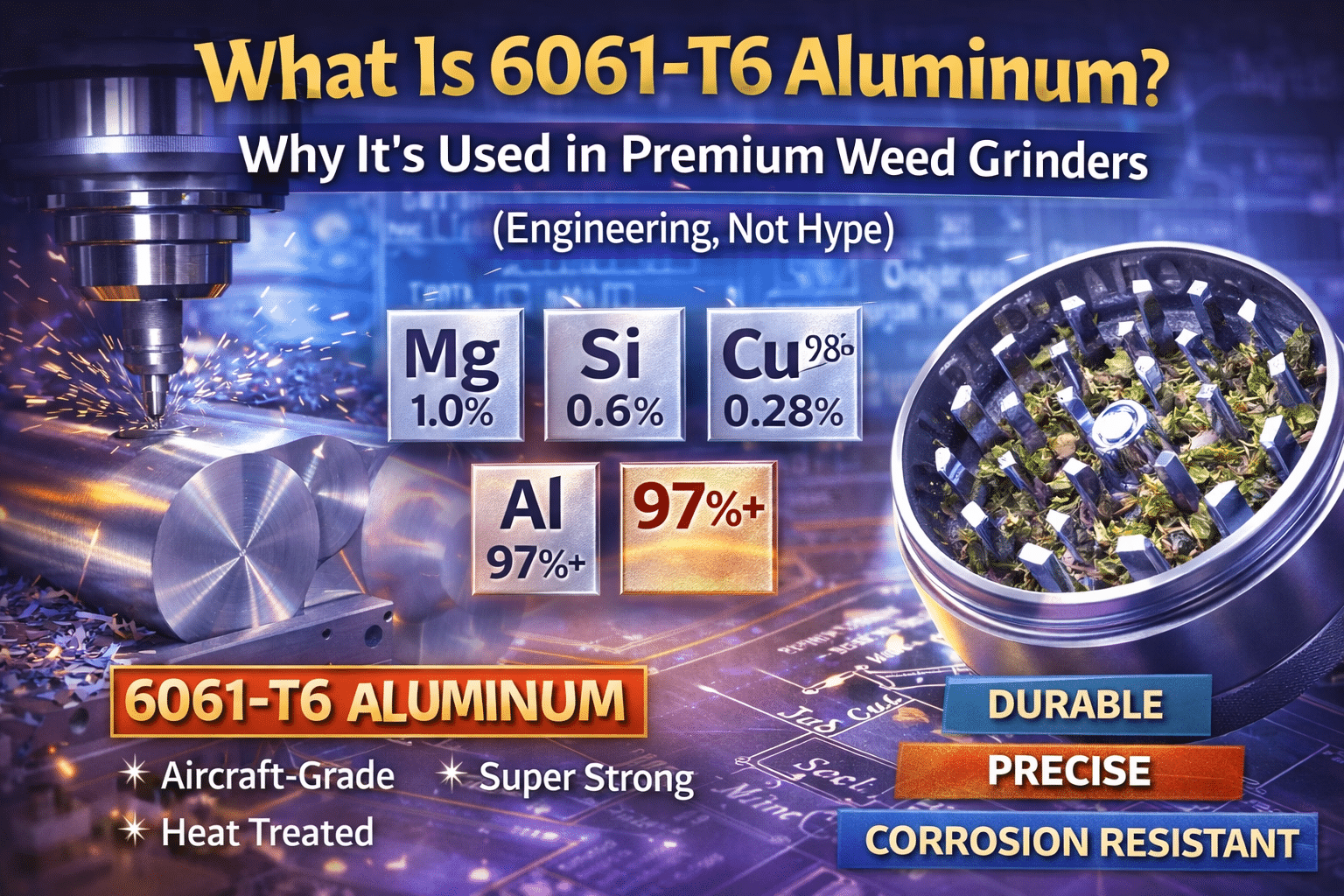

6061 aluminum is primarily aluminum, alloyed with:

- Magnesium

- Silicon

That combination creates a material that:

- Machines cleanly

- Resists corrosion

- Holds tight tolerances

- Balances strength with weight

This isn’t marketing language — it’s metallurgy.

What Does “T6” Mean?

The T6 temper means the aluminum has been:

- Solution heat-treated

- Artificially aged

This process:

- Increases strength

- Improves wear resistance

- Stabilizes the grain structure

- Reduces deformation under load

In plain terms: 6061-T6 stays true over time, even under constant friction and pressure — exactly what a grinder experiences.

Why 6061-T6 Is Ideal for Weed Grinders

A grinder is a mechanical tool. Every grind involves:

- Metal-to-metal contact

- Repeated torque

- Fine tolerances

- Resin abrasion

6061-T6 performs exceptionally well in this environment.

1. Precision Machining (Critical for Grind Quality)

6061-T6 machines cleanly on CNC equipment, allowing:

- Sharp, consistent tooth geometry

- Smooth mating surfaces

- Perfect lid alignment

- Predictable grind output

This precision is why high-quality grinders feel smooth instead of crunchy:

https://tahoegrinderco.com/product-category/all-products/

2. Strength Without Excess Weight

6061-T6 is strong enough to resist:

- Tooth deformation

- Thread wear

- Warping over time

But it’s not overly dense, which keeps grinders:

- Comfortable to handle

- Easy to control

- Balanced during grinding

That balance matters most in daily-use grinders:

https://tahoegrinderco.com/product-category/all-products/3-piece-weed-grinders/

3. Excellent Corrosion Resistance

Grinders deal with:

- Moisture from flower

- Resin oils

- Cleaning cycles

6061-T6 naturally resists corrosion, especially when paired with proper surface treatment.

That’s why it’s preferred over mystery alloys or cast metals that oxidize, pit, or degrade.

Why 6061-T6 Beats Zinc Alloy (By a Mile)

Many cheap grinders use die-cast zinc alloy because it’s fast and inexpensive to produce. The performance difference is not subtle.

Zinc Alloy Problems:

- Cast, not machined

- Inconsistent material purity

- Softer and more brittle

- Coatings flake or chip

- Poor tolerance control

6061-T6 avoids all of this.

That’s why premium manufacturers don’t touch zinc for grinders meant to last:

https://tahoegrinderco.com/product-category/all-products/2-piece-weed-grinders/

Why 6061-T6 Is Better Than “Mystery Aluminum”

Some grinders claim to be “aluminum” without specifying alloy or temper.

That’s a red flag.

Without a specific alloy:

- Strength is unknown

- Wear behavior is unpredictable

- Machining quality varies wildly

6061-T6 removes the guesswork. Engineers know how it behaves — and users feel the difference.

Surface Finish Matters: Why 6061-T6 Is Paired With Anodizing

6061-T6 aluminum is ideal for anodizing, which is a major reason it’s used in premium grinders.

Anodizing:

- Converts the surface into a hardened oxide layer

- Does not peel or flake

- Is food-safe and inert

- Improves wear resistance

Painted or coated metals can chip. Anodized aluminum does not.

This is critical for multi-chamber grinders with screens and mating surfaces:

https://tahoegrinderco.com/product-category/all-products/4-piece-weed-grinders/

Why Engineers Choose 6061-T6 (Not Marketing Teams)

In real engineering environments, material selection is based on:

- Predictability

- Manufacturability

- Performance under load

- Longevity

6061-T6 is used across industries because it works, not because it sounds impressive.

That same logic applies to grinders designed as tools, not novelties.

6061-T6 in Different Grinder Styles

2-Piece Grinders

- Smooth rotation

- Minimal binding

- Long thread life

https://tahoegrinderco.com/product-category/all-products/2-piece-weed-grinders/

3-Piece Grinders

- Stable chamber alignment

- Consistent grind texture

- Reduced resin smear

https://tahoegrinderco.com/product-category/all-products/3-piece-weed-grinders/

4-Piece Grinders

- Screen integrity

- Structural stability

- Reduced clogging over time

https://tahoegrinderco.com/product-category/all-products/4-piece-weed-grinders/

What 6061-T6 Does Not Mean

Let’s be clear.

6061-T6 does not mean:

- Indestructible

- Maintenance-free

- Better than all other alloys in every case

It means appropriate, proven, and engineered.

And that’s exactly what you want in a grinder.

Final Takeaway: 6061-T6 Is a Real Spec for Real Tools

In 2026, premium weed grinders are moving away from:

- Cast metals

- Decorative coatings

- Buzzword materials

And toward:

- Specific alloys

- Precision machining

- Durable surface treatments

6061-T6 aluminum checks every box:

- Strong

- Lightweight

- Corrosion-resistant

- Machinable

- Proven

That’s why it’s used in grinders designed to perform consistently — session after session, year after year.

When a company tells you the exact alloy and temper, they’re not selling hype — they’re showing their work.